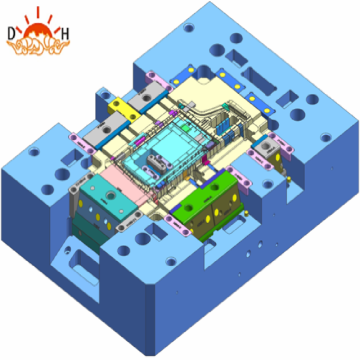

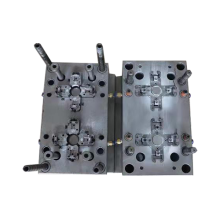

Optical Plastic parts injection Mould

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25-30 Days |

| Packaging: | Standard exported Wooden box packed, Fumigation process(upon required) |

|---|---|

| Brand: | DoHform |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Kunshan,China |

| Port: | Shanghai,Ningbo,China |

Click on the follow link to find out more information: https://www.dhform.com/acoustic-and-optical-plastic-parts-mold/

Company Info

- Company Name: DongHui Mold Machinery Co.Ltd

- Representative: Ding Huan Chen

- Product/Service: Injection Molds , Plastic Moulds , Metal Stamping Dies , Mass Production Injection Molding , Metal Stamping Parts Processing , Mold Base

- Capital (Million US $): US$1 Million - US$2.5 Million

- Year Established: 2010

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 51% - 60%

- No. of Production Lines: 50

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: No.298 Jianlin Road,Zhangpu Town,Kunshan City,215300,Suzhou,Jiangsu Province, China.

- Contact Person: Mr. Chan

- Tel: 86-512-57999246

Premium Related Products

Other Products

Hot Products

pump used EPDM o ringviton seals o ring hot-sale high quality productAS568 rubber o ring supplier beautiful color mini elastic2014 best selling High quality rubber o ring supplier2014 best quality vmq o rings wholesale priceMini Color Red Seal O RingsMini Purple Seal Durable O Rings ChinaChina Popular Hot Sale Viton Sealing O Ring2014 Factory supply best quality rubber o-ring sealChina cheap products best quality broad band ringChina manufacturer supply purple rubber o ring for sealingBest new design cheap products copper ring gasketFashion and high quality cheap seal o ringBest selling China high quality sealing rubber with double functionHigh quality customized rubber seal ringDifferent size rubber assorted colors o ring