High profitable waste plastic recycling machine to oil

Basic Info

Model No.: LN-2800*6600

Product Description

High profitable waste plastic recycling machine to oil

Plant information

Specifications of waste plastic recycling machine to oil

| NO. | Raw materiaMol | Note |

| 1 | LN-2200*6600 | 5-6 TONS |

| 2 | LN-2600*6600 | 7-8 TONS |

| 3 | LN-2800*6600 | 10TONS |

| 4 | LN-2800*7200 | 12TONS |

| More specifications can make customized. | ||

The Raw Material For waste plastic recycling machine to oil

| . | Raw material | Note |

| 1 | Waste tyre | Steel tyre ,Nylon tyre ,Bick tyre |

| 2 | Waste plastic | PE,PVC,Waste washed mixture plastic from waste Paper Factory |

| 3 | Waste rubber | Shoes Soles,Cable Skin |

| 4 | oil sludge,waste oil sludge |

|

| We have our own lab to test the oil output rate of your raw material ,welcome you contact | ||

Advantages of waste plastic recycling machine to oil

Reactor:

1. The gear can be seperated from reactor, instead of welding on reactor. So it will not be destroyed by cycling heating.

and very easily to be re-placed

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q245R/ Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

6.Reactor for waste plastic recycling machine to oil add extra bigger locating ring.

Cooling system of waste plastic recycling machine to oil:

1. Coil pipe cooling system : there are 22-30 pipes lied in the water pond,each pipe 6 meters long, oil gas can be cooled in

larger area and longer time,thus get higher oil yield .

2. Vertical condensrs : we supply 4 cndensors, each has 44 pipes inside the condensors. Save land and

looks more neat and beautiful.

Anti-back fire device:

1. Little residual gas can not be cooled. It will recycle these gas to furnace burned to heat the reactor.

2. Water sealing disign will prevent tempering. Ensure safety.

Double dust removal device:

1. Dispose of flue gas caused by heating reactor using coal, wood, oil or natual gas.

2. Environment protection.

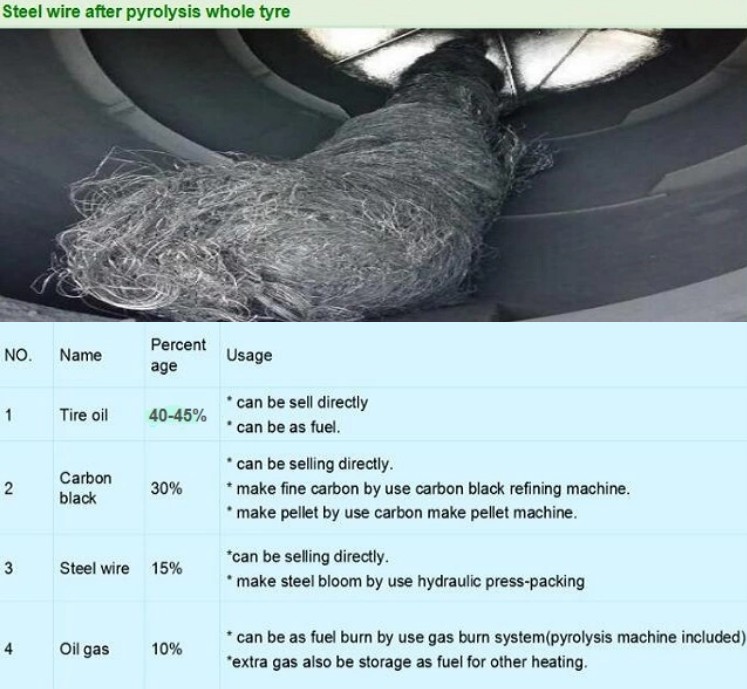

Final products of waste plastic recycling machine to oil

The machine can delivery within 15 working days after receiving deposit

Suitable container & shipping company will recommend to you to save shipping fee

More information can send inquiry to us.

Product Categories : Tyre Pyrolysis Machine > Waste Tyre Pyrolysis Recycling Machine